Acrylic Waterproof Coating for Metal Roof

Acrylic waterproof coating for metal roof is made of self-crosslinking acrylic waterproofing emulsion and filler. It is specially designed for coating on metal surface. It can be combined with woven polyester fabric to form the joints, joints and perforations of metal roofing.

Keywords:

Category:

- Product description

- Scope of Application

- Installation Methods& Vedio

- Classic Projects Reference

-

- Commodity name: Acrylic Waterproof Coating for Metal Roof

Acrylic waterproof coating for metal roof is made of self-crosslinking acrylic waterproofing emulsion and filler. It is specially designed for coating on metal surface. It can be combined with woven polyester fabric to form the joints, joints and perforations of metal roofing.

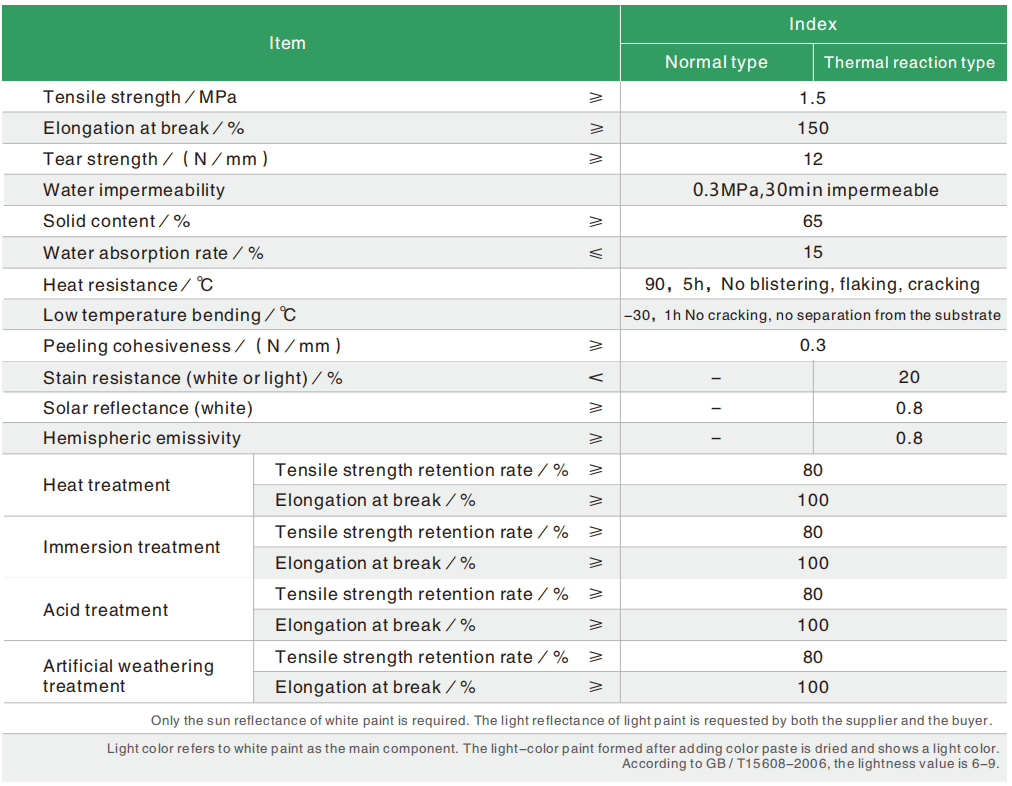

Product IntroductionAcrylic waterproof coating for metal roof is made of self-crosslinking acrylic waterproofing emulsion and filler. It is specially designed for coating on metal surface. It can be combined with woven polyester fabric to form the joints, joints and perforations of metal roofing. The complete waterproof system provides a perfect solution to solve the congenital leakage of metal roofing. At the same time, the coating material has fatigue resistance, aging resistance, low temperature flexibility and flexibility, which are completely suitable for open air environment and metal characteristics.Executive StandardJG/T 375-2012《Acrylic High Elastic Waterproof Coating for Metal Roof》Physical Index Product ClassificationAccording to the use performance, it can be divided into two types: normal type and heat reflection type.

Product ClassificationAccording to the use performance, it can be divided into two types: normal type and heat reflection type. -

Scope of Application

It is mainly used for waterproofing of roof and wall of steel structure factory. -

Construction Method● The waterproof part is determined:Metal panel lap joints, intersections with the parapet wall, fan joints, protruding roof ducts, air conditioning ducts, lighting panels, roof ridges, gutters, rivet firmware and other weak parts.● Waterproof parts treatment:A. Requirements: Ensure that the metal roof panel is firm and the waterproof parts are free of dirt and dirt.B. Treatment: If necessary, replace or add firmware, grind the dirt and dirt, remove dust and other dirt, until the metallic color is present, and then apply primer.● Construction process:1. Base treatment of each part:◎ Lap joint: Apply the primer coating, spread the 15~20cm wide sewed polyester cloth on the lap joint, and then fully coat and infiltrate with the primer coating.◎ Raised/firmware: chimney, vent, fan port, etc., need to paint around, spread the size and shape of the woven polyester cloth, paint on the cloth and fully infiltrate, to ensure that Bubble, no wrinkles.◎ Gutter: Gutters, seams, etc. need to be treated locally, and then painted, consistent with the above.2. Brush the heat reflective coating:◎ After the base layer treatment of each part is done, apply one to two heat-reflective metal roofing special waterproof coatings in the waterproof area, and the coating thickness should not be <0.5mm.◎ Reference dosage: 1.0mm thick coating film, the total amount of coating is about1.8~2.0kg/㎡.● Notes:1. Do not apply below 5 ° C or in the rain.2. After construction, before drying and film formation, care should be taken to avoid strong sunlight exposure, and rainwater erosion should be avoided.

-

Jiangsu Provincial People's Hospital

Previous page

Next page

Previous page

None

Next page

Related Products

Messages

We will contact you within one working day. Please pay attention to your email.