Reinforced TPO membrane

Thermoplastic polyolefin (TPO) waterproof membrane is a kind of thermoplastic elastic laminated waterproof material , which is made of TPO resin by Chemical copolymerization with specific formula .

Keywords:

Category:

- Product description

- Scope of Application

- Installation Methods& Vedio

- Classic Projects Reference

-

- Commodity name: Reinforced TPO membrane

Thermoplastic polyolefin (TPO) waterproof membrane is a kind of thermoplastic elastic laminated waterproof material , which is made of TPO resin by Chemical copolymerization with specific formula .

Thermoplastic polyolefin (TPO) waterproof membrane is a kind of thermoplastic elastic laminated waterproof material , which is made of TPO resin by Chemical copolymerization with specific formula .It is the best materials using for single-ply roof waterproofing .

Standard Specification

Width : 2.0m , 2.5m

Basic Thickness : 1.2mm , 1.5mm, 1.8 mm ,2.0mm

Length: 20m

Product Features

1. Strong aging resistance and stability .

2. Excellent environmental friendly performance .No chlorine ,no pollution .

3. High performance in breaking strength, tearing strength and puncture resistance

4. Good flexibility at low temperature,no crack at -40℃

5.Smooth surface with high light reflection rate which result in energy saving and pollution resistant

6.Anti-Microbiological growth, Stable size with heat aging resistance

7.Strong Chemical resistance to acid and alkali

8.High Security without open flame installation

9.Service Life: Exposed using min 20 years ; if unexposed , it can be 50-100 years .

10.TPO raw materials: polypropylene (PP) and (EPR including EPM and EPDM ) Our TPO resins Hifax made by the Catalloy process of Lyondellbasell co., LTD from Netherlands , and we used the method of copoymerization in polymerization to produce the TPO membrane with uniform distribution and small distribution size And Features of high elasticity, wide welding window, fixed installation without perforation.

11.The welding window of TPO coil is wide.

12.The artificial weathering time of Otai TPO is not less than 6500 hours.

Technical Data Standard Sheet (GB27789-2011)

No.

Test Item

Index H

L

P

1 The thickness of resin layer above the reinforcement fabric/ mm ≥ -

-

0.40

2 Tensile property Maximum Tension N/cm ≥ -

200

250

Tensile Strength Mpa ≥ 12.0

-

-

Max Tension Elongation/ % ≥ -

-

15

Breaking Elongation/ %≥ 500

250

-

3 Heating treatment size change rate % ≤ 2.0

1.0

0.5

4 Low temperature bending -40 ℃ No.Crack

5 Water impermeability 0.3Mpa, 2h Impermeable

6 Impact resistance 0.5kg, m ,impermeable

7 Anti-static load -

-

20kg impermeable

8 Seam peel strength N/mm ≥ 4.0

3.0

3.0

9 Right -angle tear strength N/mm ≥ 60

-

-

10 Trapezoid tear strength N ≥ -

250

450

11 Water absorbing capability (70 ℃, 168h)%≤ 4.0

12 Heat aging (115 ℃) Time/h 672

Appearance No bubble ,crack ,delamination , bonding and holes

Max tensile retention %≥ -

90

90

Elongation retention % ≥ 90

-

-

Tensile strength ( Max tension on )retention %≥ -

-

90

Breaking elongation retention /%≥ 90

90

-

Cold bending -40 ℃ No. Cracking

13 Chemical resistance Appearance No bubble ,crack ,delamination , bonding and holes

Max tensile retention %≥ -

90

90

Elongation retention % ≥ 90

-

-

Tensile strength ( Max tension on )retention %≥ -

-

90

Breaking elongation retention /%≥ 90

90

-

Cold bending -40 ℃ No. Cracking

14 Artificial Climate accelerating aging Time/h 1500

Appearance No bubble ,crack ,delamination , bonding and holes

Max tensile retention %≥ -

90

90

Elongation retention % ≥ 90

-

-

Tensile strength ( Max tension )retention %≥ -

-

90

Breaking elongation retention /%≥ 90

90

-

Cold bending -40 ℃ No. Cracking

Single-ply roof membrane artificial climate accelerating aging time is 2500h CERTIFICATES

FM Certificates

OTAi fire retardant thermoplastic polyolefin (TPO) waterproofing membrane was approved by FM A grade Flam retardant , Anti-Hail, Anti-Wind reach 195 PSF.

Key words:- thermoplastic polyolefin

- tpo

- concrete roof

- 60mil polyster reinforced tpo membrane

- waterproof membrane sheet

- roofing

-

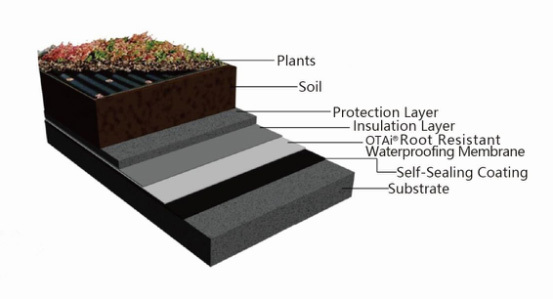

Convention centers , exhibition halls ,stadiums , library , airport terminals , industrial plants,warehouse , logistics and other building’s metal roofs , exposed concrete roofs and green roofs.

-

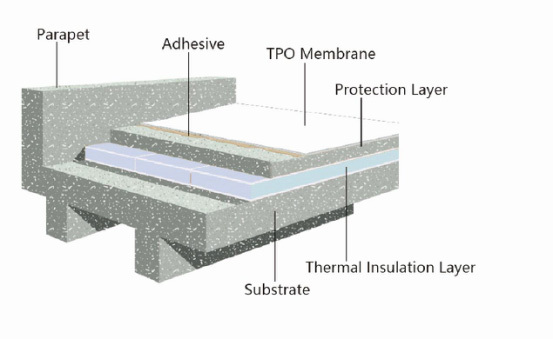

Concrete Roof Mechanical Fixation Method Metal Roof Waterproofing Roofing Details Treatment Self Adhesive Polymer Waterproof Membrane Application for Concrete Roof The installation of TPO waterproofing membrane is combined with advanced and mature technology , and complete application . Hot air welding is adopted for the overlaps of membranes, and between membrane and prefabricated accessories . The Installation are basically categorized as ballasted system, full adhered system and mechanical attachment system .

Ballasted System

The membrane is installed by adhesive or metal battens at certain area .The remaining area is not attached . Overlaps is welded by hot air. The wind uplifting force is withheld by the weight of ballasted materials .

System Features

. Suitable for all types of different substrates

. Quick installation

.Low Installation cost ;

.Excellent weathering resistance

The installation method is suitable for green roofs , driving roofs , the often step roof and non-often step roofs covered with cobble stones or prefabricated blocks.

Fully -Adhered System

The TPO membrane is adhered to base with adhesive . Overlaps is welded by hot air .

System features

. For roofs with complicated structure;

. Light weight ;

. Strong wind uplift resistance ;

. Great looking

The installation method is suitable for concrete roofs and steel roofs with high density insulation boards .

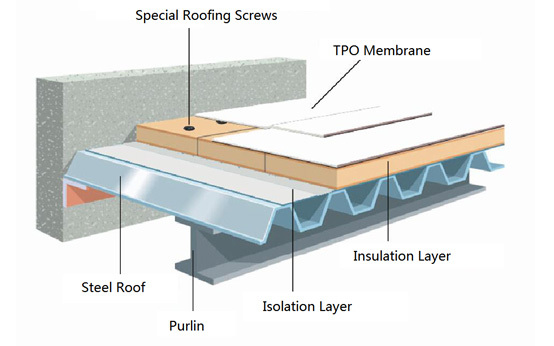

Mechanical Fixation System

The roofing membrane is installed by special roofing screws with plates or battens to the basis like structural concrete ,steel deck or wooden deck ,etc. The Overlap between the seams of the membrane sheet is welded by hot air welder .

System Features

. Easy installation

. Strong wind resist

. High performance of cost ratio

. Light Weight

The installation method is suitable for concrete roofs , steel roofs , aluminum roofs .

-

Canada Factory Renovation

Australian residential project

Saipan Resort Hotel in USA

The Airbus A330 Wide-Body Aircraft Completes &Delivers Center Custom-Built Workshop.

Tianjin FAW Toyota Motor Co. LTD.

National New Energy Vehicle

China Research the Aerodynamic Wind Tunnel Laboratory

New Generation Rocket Carrier Base

Tianjin Metro Integrated Control Center

Minmetals International Commercial Building

Haite Aircraft

Kerry Centre

Logistics University of PAPF

FAW Toyota International Logistics, Import and Export of Spare Parts Co., Ltd

Paramount Bed (China) Co., Ltd.

China Witt tianjin pharmaceutical co. LTD.

Meijiang international exhibition center phase two

Tianjin lifting equipment co. LTD.

Underground garage of beitang headquarters.

Foxconn plant

Sino-Singapore Eco-City National Animation Park

Sino-Singapore Eco-City Low-carbon experience center.

Yi Zhou Ding Fresh Cold Chain

TEDA MSD Plaza

Tianshili medical research institute.

Previous page

Next page

Previous page

Homogeneous TPO membrane

Next page

Related Products

Messages

We will contact you within one working day. Please pay attention to your email.